A rotary pulp molding machine is a type of equipment used to manufacture molded pulp products, which are eco-friendly alternatives to plastic packaging. These machines use a rotary molding process to create items from recycled paper pulp, such as egg trays, cup holders, and various types of containers.

Components and Functions

Pulp Preparation System:

Pulping Machine: This component shreds and processes waste paper into a slurry of paper fibers and water. The quality of the pulp affects the final product, so this stage is crucial.

Pulp Pump: Moves the prepared pulp from the pulping machine to the molding section. It ensures a steady flow of pulp to the molds.

Pulp Storage Tank: Stores the pulp mixture, keeping it at the right consistency and temperature until it’s needed for molding.

Rotary Molding Unit:

Rotary Mold: The core component of the machine, the rotary mold consists of multiple cavities that rotate in a circular motion. This rotation allows for continuous molding and efficient production.

Molding Station: Here, the pulp is distributed into the mold cavities. The rotary motion ensures uniform distribution and filling of the cavities.

Drying System:

Drying Oven: After molding, the wet pulp products need to be dried to harden them. The drying oven uses heat to evaporate the moisture from the products.

Drying Conveyor: Moves the molded products through the drying oven. It ensures that products are evenly exposed to heat for consistent drying.

Release and Finishing:

Mold Release Mechanism: Once the products are dried, they need to be removed from the molds. This mechanism ensures smooth and efficient release without damaging the products.

Trimming and Cutting: Excess material is trimmed, and products are cut to their final size. This step ensures that the finished products meet specific size and quality standards.

Control System:

PLC (Programmable Logic Controller): The control system manages the operation of the machine. It coordinates various stages of production, from pulp preparation to molding and drying, ensuring precise control and automation.

HGHY Double Rotary Egg Tray Pulp Moulding Machine

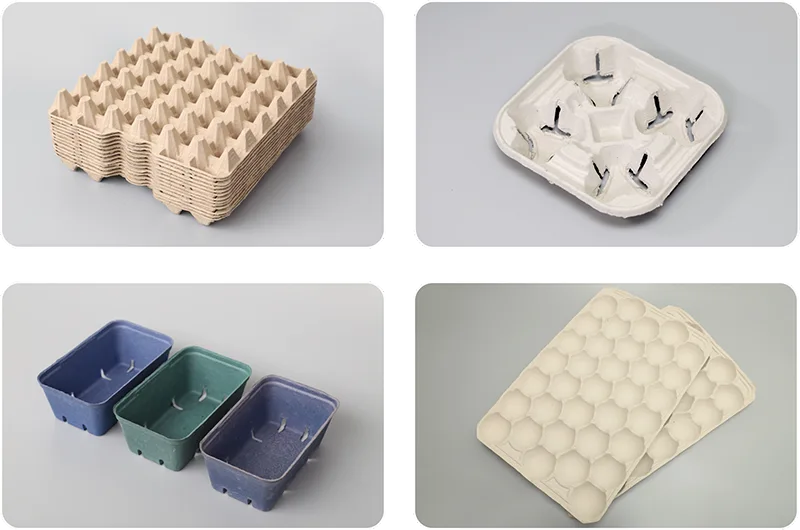

Exceeding conventional speeds, it boasts world-class performance. Double Rotary Egg Tray Pulp Molding Machine is ideal for manufacturing a range of standard products including egg trays, fruit trays, drinking cup carrier trays, bottle trays, and more with exceptional precision and efficiency.

HGHY Paper Lid Making Machine

Paper Cup Lid Making Machine from HGHY offers a rapid return on investment and boasts high cost-effectiveness. It is primarily designed for producing standard products with regular shapes, such as fruit trays, drinking cup carrier trays, egg trays, bottle trays, and more.

HGHY Pulp Molding Tableware Machine

HGHY Pulp Molding Tableware Machine is a cutting-edge technology designed for a burgeoning market. Since its launch, it has already achieved impressive sales figures, surpassing 100 units. This machine is specifically tailored for the production of various environmentally-friendly molded fiber tableware products such as plates, fast food boxes, bowls, cups, and more. Its versatility and eco-friendly attributes make it a valuable asset for businesses aiming to contribute to sustainable practices in the production of tableware.

HGHY Paper Tray Making Machine

Featuring a slight draft angle, Paper Tray Making Machine specializes in crafting premium, eco-friendly molded fiber packaging. It is well-suited for producing pulp-molded paper trays, as well as refined, high-grade linings or outer packaging for items such as mobile phones, daily necessities, and digital products, ensuring top-notch quality.

Prospects and Market Trends

Sustainability and Environmental Impact:

Growing Demand for Eco-Friendly Packaging: As global awareness about environmental issues increases, there is a strong shift towards sustainable packaging solutions. Rotary pulp molding machines play a crucial role in meeting this demand by producing biodegradable products from recycled paper.

Technological Advancements:

Improved Efficiency and Automation: Recent advancements have led to more efficient machines with better automation features. These improvements result in higher production rates, lower operational costs, and enhanced product quality.

Enhanced Customization: Modern machines offer greater flexibility and customization options, allowing manufacturers to produce a wide range of products with varying shapes and sizes.

Market Expansion:

Global Market Growth: The global market for molded pulp products is expanding, driven by regulatory measures against single-use plastics and increasing consumer preference for sustainable packaging. This growth is creating a positive outlook for rotary pulp molding machines.

Emerging Markets: Developing economies are increasingly adopting eco-friendly packaging solutions, presenting new opportunities for rotary pulp molding machine manufacturers.

Economic Benefits:

Cost-Effective Production: Rotary pulp molding machines are known for their cost-effectiveness in producing large volumes of molded pulp products. They offer a competitive advantage due to lower material costs and efficient production processes.

Innovation and Diversification:

New Applications: Ongoing research and innovation are leading to new applications for molded pulp products. This diversification opens up additional markets and opportunities for rotary pulp molding machine manufacturers.

Advantages of Bagasse Pulp Molding Machine:

The Bagasse Pulp Molding Machine offers a multitude of advantages, making it an attractive choice for businesses committed to sustainability and efficiency:

Environmental Sustainability: By utilizing bagasse as its raw material, the machine reduces reliance on non-renewable resources and minimizes waste. This eco-friendly approach aligns with global efforts to combat climate change and preserve natural ecosystems.

Biodegradability: Products manufactured using the Bagasse Pulp Molding Machine are inherently biodegradable, meaning they can naturally decompose without causing harm to the environment. This characteristic makes them an ideal alternative to traditional plastics, which often contribute to pollution and environmental degradation.

Versatility: The machine’s versatility enables the production of a wide range of pulp-based products, catering to diverse packaging needs across industries such as food and beverage, electronics, and healthcare. From disposable tableware to protective packaging inserts, the possibilities are virtually endless.

Cost-Effectiveness: Despite its advanced technology and eco-friendly features, the Bagasse Pulp Molding Machine offers cost-effective solutions for businesses. By streamlining production processes and minimizing material costs, companies can achieve significant savings while contributing to sustainability goals.

Continuous Operation: With its reliable performance and robust design, the machine is capable of operating 24 hours a day, ensuring uninterrupted production schedules and timely deliveries. This level of efficiency and productivity further enhances its appeal to businesses seeking dependable packaging solutions.

HGHY: A Leading Manufacturer of Pulp Molding Machines

HGHY is a renowned name in the field of pulp molding machinery. With a reputation for innovation and quality, HGHY offers a range of machines suitable for various applications, including egg box production. Their machines are characterized by:

– Advanced Technology: HGHY machines incorporate cutting-edge technology, ensuring efficiency and precision in production.

– Customization Options: HGHY provides tailored solutions to meet specific production requirements, from small-scale operations to large-scale industrial setups.

– Environmentally Friendly: HGHY’s machines are designed with sustainability in mind, utilizing recycled materials and minimizing waste.

In summary, rotary pulp molding machines are essential for the production of sustainable, biodegradable packaging products. With ongoing technological advancements and a growing global focus on environmental sustainability, the prospects for these machines are promising. The market is set to expand as demand for eco-friendly solutions increases, driven by both consumer preferences and regulatory pressures.