Double Rotary Egg Tray Machine

Unique Technology in China

Exceptional speed surpassing the standard, demonstrating a world-class level of performance.

– High Productivity Production Line

Main Features

- Meticulously designed with a purely mechanical synchronous power system.

- Side-by-side large maintenance doors for easy access.

- Enhanced wet-to-dry ratio in the production process for optimal efficiency.

- Automatic cleaning for both forming and transfer molds.

- Efficient heat exchange and recovery for hot shower water.

- Automated processes for conveying, stacking, and counting.

- Auto-compression and packaging capabilities.

Technical Parameters

| Model | 7000B2C | 9000B2C | 12000B2C |

| Molding Machine | High Speed Double Rotary Technology | ||

| Molding Faces | 6 Faces Forming + 6 Faces Transfer | ||

| Platen Size | 850 × 460 mm | 1250 × 460 mm | 1650 × 460 mm |

| Drops per Minute | 50-60 Drops | ||

| Drying Oven | 10 Layers | ||

| Drying Energy | Diesel / Natural Gas / LPG / LNG etc, or Boiler System of Steam / Conduction Oil | ||

| Standard Capacity / Hr | 7,000 pcs | 9,000 pcs | 12,000 pcs |

| Standard Capacity / Day | 168,000 pcs | 216,000 pcs | 288,000 pcs |

| Floor Plan (m) | 72 × 18 × 8 | 90 × 18 × 8 | 90 × 24 × 8 |

| Labor / Shift | 5~6 | 5~6 | 6~7 |

| Raw Material | Waste Paper | ||

| Max Product Height | 70 mm | ||

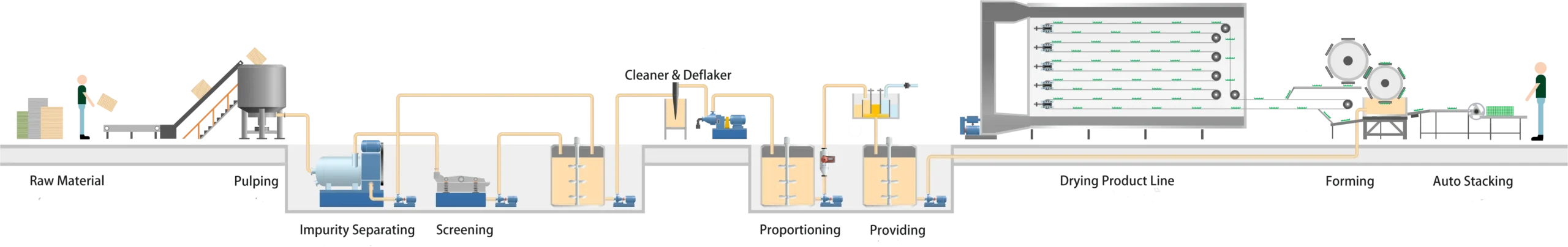

Production Process

Project Cases

Applications

Raw Material

Waste Paper

The conventional double rotary paper egg tray making machine employs waste paper as its primary raw material, encompassing discarded newspapers, used cardboard, remnants from paper mills, or surplus from printing facilities. The production process of pulp-molded products is characterized by its adaptable and malleable structure, allowing for substantial elastic-plastic deformation, thereby providing an effective buffering function. This production process is straightforward and swift, and the resulting products can be recycled and repurposed in the future.

Frequently Asked Questions

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

The rate of return is high, and it usually pays back in 2-3 years.

HGHY has helped more than 300 clients in over 60 countries setting up their plants with leading capacity and superior quality production.