HGHY Paper Cup Lid Making Machine

Why choose cup lid making machine ?

Sold out for more than 150 lines

– Rotary forming machine

Main Features

- Swift return on investment, exceptional cost-effectiveness.

- Outstanding performance thanks to rotary forming technology.

- Compatible with a highly efficient 6-pass dryer.

- Yields stronger and less deformed products.

Technical Parameters

| Model | ZJWD-9575Y | ||

| Machine Structure | Prepressing Station x1, Hotpress Upper Station x1, Transfer Station x1, Forming Station x1, Hotpress Lower Station x1 | ||

| Platen Size | 950 × 750 mm | ||

| Working Pressure | Prepressing 15 Ton, Hotpress 40 Ton | ||

| Cycle Time | 40-120 Seconds for Most Products | ||

| Heating Energy | Electricity / Conduction Oil | ||

| Raw Material | Paper Pulp | ||

| Max Product Height | 80 mm / Can Be Customized for Deeper Product | ||

| Production Application | Coffee Cup Lid, Rigid Box, etc Packagings with Critical Draft Angle, R Angle or Complicated Structure | ||

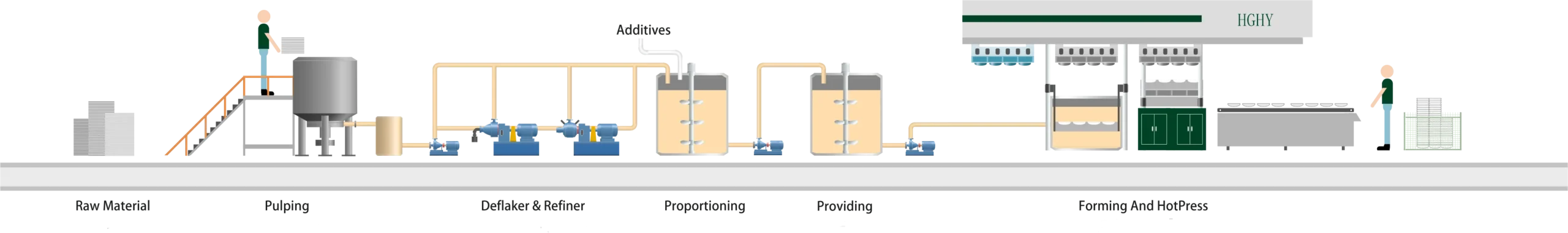

Production Process

How paper lid making machine works? Paper Cup Lid Making Machine is composed of pulping system, forming system, drying system, auxiliary system.

Project Cases

Applications

Raw Material

Waste Paper

The raw material of the Paper Lid Making Machine is traditional pulp molding machines, which typically use waste paper. This includes items like waste newspapers, discarded carton paper, scraps from paper mills, or excess from printing plants, among others. The production process of pulp molded products is characterized by their flexible structures, allowing them to undergo significant elastic-plastic deformation, providing effective buffering. They are also quick and straightforward to produce and can be recycled and reused later on.

Frequently Asked Questions

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

The rate of return is high, and it usually pays back in 2-3 years.

HGHY has helped more than 300 clients in over 60 countries setting up their plants with leading capacity and superior quality production.