HGHY Paper Pulp Packaging Manufacturers

Customized In Various Sizes

High efficient and lower consumption drying line

– Flexible configuration options;

Main Features

- Easy and adaptable operation and maintenance.

- Reduced mold matching costs.

- Option for both semi-automatic and fully automatic types.

- Highly efficient with lower energy consumption for drying.

Technical Parameters

| Model | Reciprocating Production Line | ||

| Machine Structure | Forming Upper Platen x1; Forming Lower Platen x1; If Platen size is bigger, Upper platen move out automatically, Or to match with dryer by auto feeding. | ||

| Platen Size | Different sizes of plates would be customized on demand | ||

| Forming Method | Reciprocating | ||

| Matching Dryer | Natural Drying or Drying Tunnel Or single Layer Dryer as Optional | ||

| Heating Type | Thermal Oil, Natural Gas or Steam Heating | ||

| Control By | PLC + Touchscreen | ||

| Designed Capacity | Depends on Products | ||

| Product Height Range | ≤150mm | ||

Production Process

How paper pulp packaging manufacturersn works? Disposable Container Making Machine is composed of pulping system, forming system, drying system, auxiliary system.

Project Cases

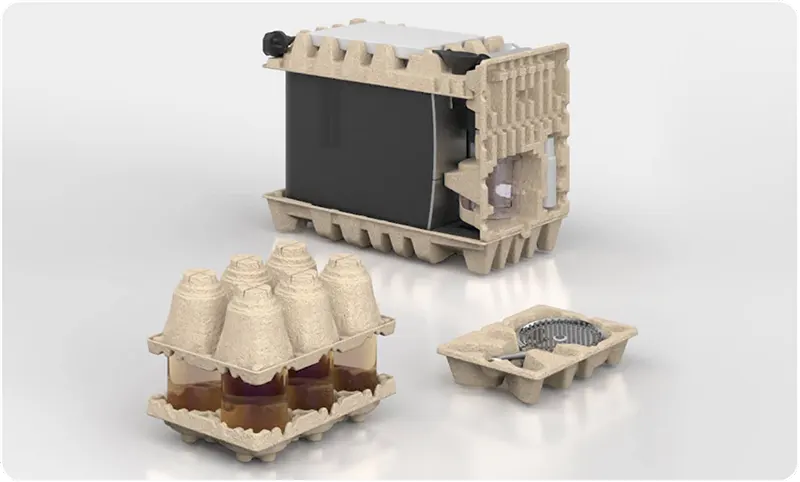

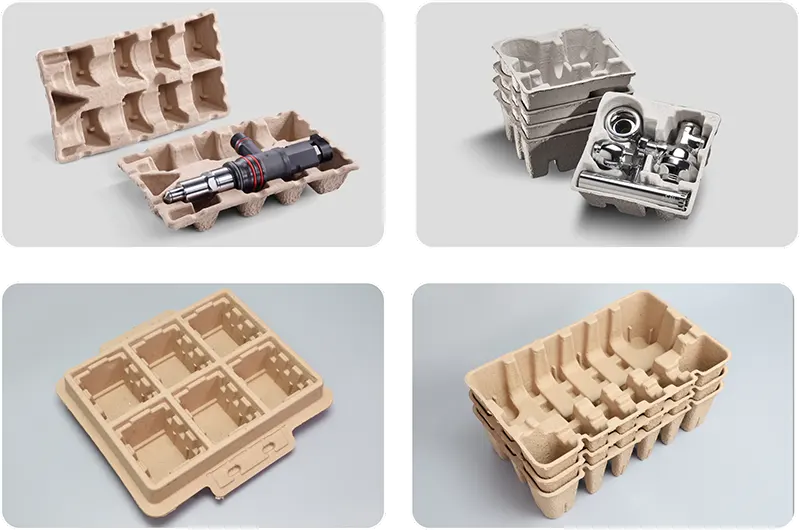

Applications

Raw Material

Waste Paper

The raw material of HGHY Paper Pulp Packaging Manufacturers is waste paper, which includes discarded newspapers, used cardboard, scraps from paper mills, or remnants from printing plants. The production process characteristics of products molded from pulp dictate that their structures are pliable, allowing for significant elastic-plastic deformation, ultimately serving as effective buffers. This method is both rapid and straightforward, and the resulting products can be easily recycled and reused at a later stage.

Frequently Asked Questions

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

The rate of return is high, and it usually pays back in 2-3 years.

HGHY has helped more than 300 clients in over 60 countries setting up their plants with leading capacity and superior quality production.