Disposable Tableware Production Line

Simple, Advanced and Rapid Development

Since its launch, this new technology created for a new market has sold more than 100 units.

Main Features

- High cost-effective intelligent control system;

- Flexible, accurate, and stable production;

- Safe and easy operation and maintenance;

- Remote intelligent production monitoring;

- Integrated design for trimming and stacking;

- Intelligent connection of processes by robots.

Technical Parameters

| Model | JZC2-9895Q | ||

|---|---|---|---|

| Product Application | Common Tableware, Cup | ||

| Daily Capacity | 800 KG (±10%) | ||

| Platen Size | 980 × 940 mm | ||

| Heating Energy | Electricity / Thermal Oil | ||

| Forming Method | Reciprocating | ||

| Hotpress Method / Pressure | Pneumohydraulic System / Max 30 Tons Pressure | ||

| Trimming Method / Pressure | Hydraulic System / Max 60 Tons Pressure | ||

| Safety Protection | Self-locking & Auto-stop Design | ||

| Max Product Height / Thickness | 80 mm / 0.8 mm | ||

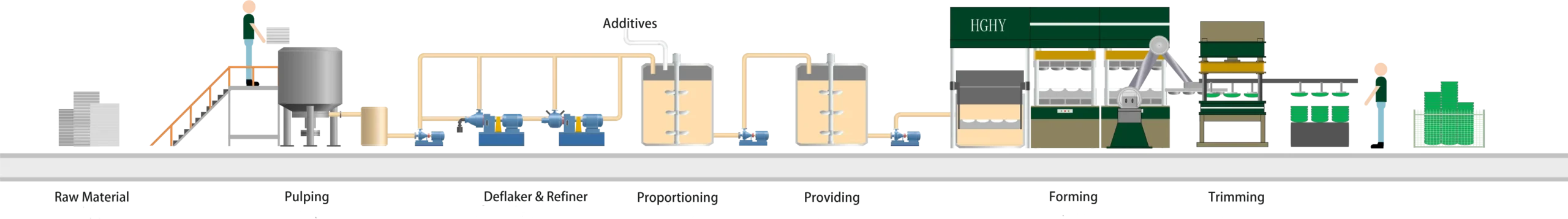

Production Process

The Disposable Tableware Making Machine consists of a pulping system, multiple sets of main systems (including forming, hot pressing, trimming, stacking, and robots), auxiliary systems, for producing pulp-molded tableware and food packaging.

Project Cases

Applications

Raw Material

Bagasse Pulp

The Disposable Tableware Making Machine utilizes bagasse, a by-product of sugar mills, as its primary raw material for paper fiber. Bagasse fibers, with an average length ranging from 1.0 to 2.34mm and an overall fiber length of 1.47 to 3.04mm, offer moderate strength and toughness. This makes bagasse highly suitable for crafting pulp molding products. Currently, bagasse, derived from sugarcane, is extensively used in the manufacturing of lunch boxes and tableware. Moreover, it is employed in the production of premium mobile phone holders and cosmetic packaging.

Bamboo Pulp

The Disposable Tableware Making Machine utilizes fast-regenerating bamboo, an eco-friendly, odorless material with natural antibacterial properties. Bamboo pulp, derived from varieties like Moso and Phoebe bamboo, is processed using sulfate and caustic soda methods, resulting in a fine, soft pulp with high bulk and tear, and lower bursting and tensile strength, yet it maintains notable mechanical resilience.

Wood Pulp

The Disposable Tableware Making Machine utilizes wood pulp, which is derived from wood. Based on factors such as pulping materials, methods, and intended uses, wood pulp can be broadly categorized into two types: coniferous wood and hardwood.

Frequently Asked Questions

The estimated production time will be around 130 days, from the receipt of order, deposit payment and/or L/C.

Our company will arrange 2 people as guide installers, and the customer will arrange installers. It usually spents 60-90 days that depends on the number of equipment purchased.

The rate of return is high, and it usually pays back in 2-3 years.

HGHY has helped more than 300 clients in over 60 countries setting up their plants with leading capacity and superior quality production.